What is a Defoamer

A defoamer, also known as an antifoam chemical, is a specialized additive designed to eliminate or reduce foam formation in liquids during industrial and commercial processes. Foam can cause operational challenges such as overflowing, reduced efficiency, and product defects. Defoamers act to control this unwanted foam, ensuring smooth and consistent production.

How Defoamers Work

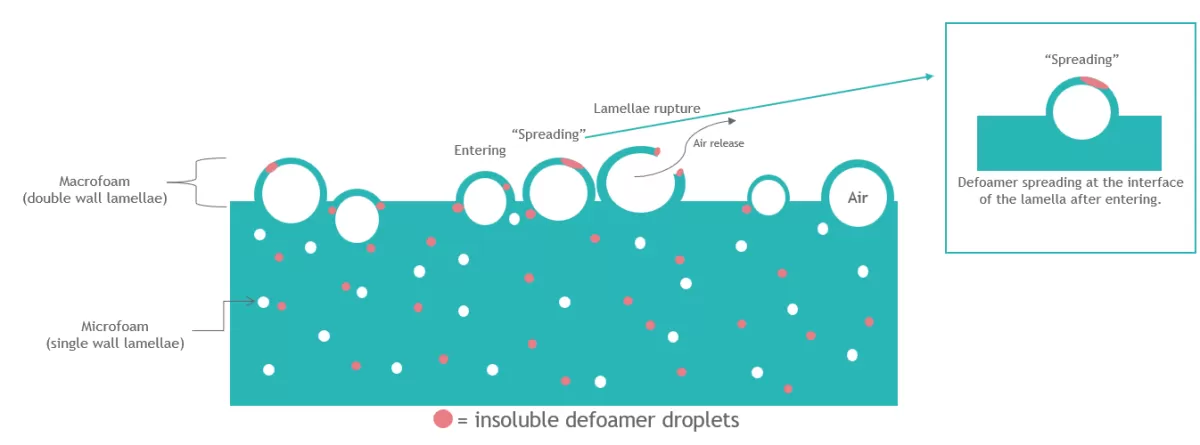

Defoamers function by disrupting the surface tension of foam bubbles, causing them to collapse quickly. They achieve this by spreading rapidly over the foam surface or by penetrating the foam film, which breaks the bubbles down. This process helps to prevent foam from forming or eliminates foam that has already appeared, improving overall process efficiency.

Common Synonyms and Related Terms

- Antifoam agents

- Foam controllers

- Silicone defoamers (a subtype based on silicone compounds)

- Non-silicone defoamers (alternative chemical formulations)

- Industrial defoamers (used broadly across manufacturing sectors)

Understanding the role of defoamers and the types available is essential for industries looking to solve foam-related problems effectively and maintain high-quality output.

Types of Defoamers and Blissam’s Offerings

When it comes to choosing the right defoamer, understanding types of defoamers makes a big difference. At Blissam, we offer a wide range tailored to meet the unique demands of the U.S. market, focusing on quality and reliability.

Silicone-Based Defoamers

Silicone defoamers are the most common and effective antifoam chemicals used across many industries. They work by spreading rapidly on foam surfaces and breaking down bubbles quickly. These defoamers are especially effective in wastewater treatment, paints, and coatings, where tough foam control is needed.

- Highly efficient at breaking tough foam

- Stable under extreme conditions

- Often the go-to for industrial defoamer applications

Non-Silicone Defoamers

For customers looking for alternatives or working in sensitive environments like food and beverage, non-silicone defoamers are a great choice. Made from oils, esters, or other polymers, they offer foam control without silicone’s typical residue. These are often preferred when food-grade defoamers or eco-friendly options are necessary.

- Suitable for cleaner processes

- Ideal for food production and some coatings

- Often biodegradable and environmentally friendly

Water-Based vs Oil-Based Defoamers

The base of the defoamer influences its application and effectiveness:

- Water-based defoamers mix easily in aqueous systems, making them perfect for wastewater treatment and pulp and paper industries.

- Oil-based defoamers excel in controlling foam in oil-rich environments, such as lubricants or certain coatings.

Both types have their place, and Blissam offers formulations tailored to your exact needs.

Blissam’s Defoamer Solutions

At Blissam, we understand that no two foam problems are the same. Our defoamer range includes:

- Silicone and non-silicone defoamers

- Water and oil-based formulations

- Custom blends made for specific industries like paints, food processing, or wastewater

- Eco-friendly and food-grade options for sustainable and regulatory-compliant solutions

Our expertise as a chemical defoamer supplier ensures you get the best product tailored to your operational needs, helping you tackle foam efficiently without compromising on quality or compliance.

Applications of Defoamers Across Industries

Defoamers play a vital role in reducing unwanted foam in many industrial processes. Their use improves efficiency, product quality, and overall operations. Here’s a deeper look into where defoamers are commonly applied and why they matter.

Wastewater Treatment

In wastewater treatment, foam formation is a common challenge due to organic matter, surfactants, and aeration processes. Excess foam can hinder equipment, slow down treatment, and cause operational issues.

- Defoamers help break down foam quickly, ensuring smooth aeration and sludge handling.

- This leads to improved treatment efficiency and easier maintenance.

- Eco-friendly, industrial defoamers are often preferred to meet environmental regulations.

Food and Beverage Industry

Foam in food and beverage processing can cause problems such as:

- Difficulty in measuring and filling,

- Poor product consistency,

- Contamination risks due to foam overflowing.

Using food-grade defoamers, which are safe and compliant with health standards, helps:

- Control foam during mixing, fermentation, and packaging,

- Maintain product quality and appearance,

- Improve production speed.

Paints and Coatings

In the paints and coatings industry, foam forms during mixing, stirring, and application. Foam can create bubbles, defects, and uneven finishes.

- Silicone and non-silicone antifoam chemicals reduce foam formation,

- They help produce a smooth, flawless product surface,

- Enhance the durability and look of coatings.

Pulp and Paper Industry

Foam is a persistent challenge in pulp and paper manufacturing due to the presence of surfactants and chemicals.

- Excess foam can cause operational delays, waste, and defects in paper quality.

- Using tailored defoamer solutions helps control foam in processes like pulping, washing, and paper formation,

- This results in consistent product quality and less downtime.

Other Industries

Defoamers are also crucial in various other sectors such as:

- Chemical manufacturing – to improve reaction consistency,

- Textile processing – to manage foam in dyeing and finishing,

- Oil and gas – where foam control impacts separating and refining,

- Pharmaceuticals – where precise foam control ensures product purity.

Across all these industries, selecting the right chemical defoamer supplier and product type is essential for optimal results.

By understanding the specific needs of each industry, we can provide the best defoamer applications that improve operational efficiency and product quality across the board.

Benefits of Using Defoamers in Industrial Processes

Using defoamers offers several significant advantages across various industries, making them essential for smooth operations and product quality. Here’s how they bring value:

Improved Operational Efficiency

Defoamers eliminate unwanted foam quickly and effectively, which can otherwise cause process delays, equipment malfunctions, or overflow issues in manufacturing and treatment plants. Reduced foam leads to:

- Smoother processing times

- Less downtime for cleaning and maintenance

- Enhanced equipment lifespan by preventing foam-related damage

Cost Savings

By controlling foam, you can reduce raw material waste and energy costs. Foam often causes product inconsistencies and inefficient machinery use, driving up expenses. Key cost benefits include:

- Lower scrap rates and rework

- Decreased need for costly repairs

- Optimized chemical usage in formulations

Consistent Product Quality

Foam interferes with mixing, coating, or formulation processes, potentially ruining the final product. Using defoamers ensures:

- Uniform texture and appearance in paints, coatings, and food products

- Maintaining strict quality standards essential for customer satisfaction

- Reliable performance in sensitive applications like food-grade or pharmaceutical products

Reduced Environmental Impact

Eco-friendly and biodegradable defoamers help companies meet environmental regulations while reducing their ecological footprint. Benefits include:

- Less chemical discharge into wastewater systems

- Compliance with local and federal environmental laws

- Support for sustainable manufacturing practices

By choosing the right defoamer, you not only solve immediate foam issues but also strengthen overall production efficiency and sustainability—critical factors for U.S. businesses today. For more about chemicals used in processes like coating, you might also find our insights on resin-based composites helpful.

How to Choose the Right Defoamer for Your Needs

Selecting the right defoamer or antifoam chemical is crucial for maximizing efficiency and ensuring smooth operations across various industries. Here’s what to consider when deciding on the best defoamer for your specific application.

Factors to Consider When Choosing a Defoamer

-

Type of Foam and Process Conditions

Identify whether the foam is light, stable, or persistent. Different defoamers, such as silicone defoamers or non-silicone defoamers, work better depending on foam type. Also, consider temperature, pH, and the nature of the system (water-based or oil-based), which heavily influence performance.

-

Industry and Regulatory Requirements

Some industries like food and beverage need food-grade defoamers that meet strict safety standards. Others, such as wastewater treatment or pulp and paper, may prioritize eco-friendly options to reduce environmental impact.

-

Compatibility with Your Product and Process

Your existing formulations and equipment need to work well with the defoamer. This prevents any unintended side effects like product contamination or equipment corrosion.

-

Cost and Efficiency

Balance between upfront cost and long-term savings. Efficient defoamers reduce downtime and product defects, often saving money over time.

Testing and Customization Are Key

Before fully adopting a defoamer, testing is essential. Lab trials help confirm how a defoamer behaves under your unique operating conditions. This step avoids costly mistakes and optimizes performance.

Many suppliers, including Blissam, offer customized defoamer formulations. Tailored solutions mean better foam control, improved product quality, and longer-lasting results.

Consult Experts for the Best Results

Choosing the right defoamer can get complicated due to technical variables and industry standards. Working with a trusted chemical defoamer supplier who understands your specific needs will make the process smoother.

Experts can guide you through product selection, testing, and ongoing support, ensuring that you have the ideal defoamer to boost your operation’s efficiency and product quality.

By focusing on these factors, you can confidently select a defoamer that meets your operational demands and contributes to cost savings and sustainability goals.

Common Myths About Defoamers You Should Know

Defoamers play a crucial role in many industries, but there are some misconceptions that often confuse users. Let’s clear up the top myths about defoamers and shed light on how they really work.

Myth 1 All Defoamers Are The Same

Not true. Defoamers vary widely depending on their chemical makeup, usage, and application. There are silicone-based defoamers, non-silicone defoamers, oil-based, and water-based types—all designed for specific needs. For example:

- Silicone defoamers are great for tough industrial foams.

- Non-silicone options work well for food-grade or eco-friendly applications.

- Water-based defoamers suit aqueous systems better.

Choosing the wrong type can impact performance, so it’s important to consider the application.

Myth 2 Defoamers Harm The Environment

This is a common concern, but many modern defoamer formulations are eco-friendly. Chemical defoamer suppliers, including us, develop products that minimize environmental impact. For example:

- Biodegradable and non-toxic defoamers are increasingly popular.

- Water-based and non-silicone defoamers often have lower environmental footprints.

By selecting the right defoamer type, you can maintain operational efficiency while staying green.

Myth 3 Defoamers Are Only For Heavy Industry

Defoamers are not just for heavy industries like pulp and paper or wastewater treatment. They are essential in many sectors, such as:

- Food and beverage production (using food-grade defoamers).

- Paints and coatings for smoother finishes.

- Even small-scale or specialty manufacturing processes.

Defoamers are versatile and valuable across a broad range of applications—not just the big industrial players.

Understanding these myths helps you make smarter choices when buying defoamers. Choosing the right product tailored to your needs improves efficiency, saves costs, and supports sustainability—all important for any business in the U.S. market.

Why Choose Blissam for Your Defoamer Needs

When it comes to industrial defoamers, choosing the right supplier can make all the difference. Here’s why Blissam stands out as a top choice for businesses across the United States:

Brand Expertise

Blissam brings years of experience in manufacturing and supplying high-quality chemical defoamers tailored to a variety of industries. Our deep knowledge of both silicone defoamers and non-silicone defoamers means we understand the unique challenges your operation faces. We focus on delivering solutions that work, backed by consistent research and innovation.

Extensive Product Range

Whether you need water-based or oil-based defoamers, food-grade options, or specialty formulas for wastewater treatment and paints, Blissam offers a comprehensive product lineup. Our portfolio covers everything from standard antifoam chemicals to customized blends, ensuring you find the perfect match for your process needs without any compromise.

Commitment to Sustainability

Blissam takes environmental responsibility seriously. We provide eco-friendly defoamers designed to reduce ecological impact without sacrificing performance. Our manufacturing processes emphasize safety and sustainability, aligning with the growing demand for greener industrial solutions nationwide.

Global Reach with Local Support

Though we operate globally, Blissam understands the specific requirements of U.S. industries. Our customer service teams and technical experts are based locally to provide quick assistance, technical support, and on-site consultations. This blend of worldwide capability and local focus ensures seamless supply and service wherever you are.

Get in Touch

Ready to improve your operations with effective, reliable defoaming solutions? Contact Blissam today to discuss your needs or request a sample. Let us help you enhance your product quality, save costs, and operate sustainably with the right industrial defoamer.

Explore more about our chemical expertise and solutions on our related pages like what is cured resin to discover how Blissam supports your broader manufacturing processes.

FAQs About Defoamers and Their Uses

What is a defoamer and how does it work

A defoamer, also called an antifoam chemical, helps eliminate foam buildup in liquids by breaking the foam’s surface tension. It disperses and collapses bubbles quickly, preventing foam from interfering with industrial processes or product quality.

What are the common types of defoamers available

The main types are silicone-based defoamers and non-silicone defoamers. Silicone defoamers work well in many applications due to their effectiveness and stability, while non-silicone options are preferred where silicone might affect the product’s finish or safety, such as in food-grade formulations.

Can I use water-based and oil-based defoamers interchangeably

No. Water-based defoamers are designed for aqueous systems like wastewater or paper pulp, while oil-based defoamers suit oil-rich environments such as coatings or adhesives. Choosing the wrong base could reduce defoamer efficiency and cause problems.

Are defoamers safe for food and beverage applications

Yes, but always use food-grade defoamers specifically designed for these sensitive uses. They comply with safety regulations and don’t compromise flavor or safety.

How do defoamers improve operational efficiency

Defoamers reduce foam-related equipment damage, prevent overflow and keep production lines running smoothly. Less downtime, fewer defects, and controlled foam translate to better operational efficiency and cost savings.

Are defoamers environmentally friendly

Many modern defoamers are formulated to be eco-friendly and biodegradable, minimizing environmental impact while maintaining performance. Choosing the right type is key to meeting sustainability goals.

How do I select the right defoamer for my industry

Consider factors like your process type, foam causes, regulatory requirements, and product compatibility. Testing and working with chemical defoamer suppliers or experts can ensure the best match for your needs.

Where can I learn more about related chemicals

For industries using resin and composite materials, check out related insights on resin chemistry here:

If you have more questions or want to explore industrial defoamer options, our team at Blissam is here to help you pick the best solution for your U.S. operations.