Understanding the Resin Curing Process and Factors Affecting Drying Time

When you mix resin and hardener, a chemical reaction called curing begins. This process is exothermic, meaning it releases heat as the resin hardens. Curing transforms the liquid resin into a solid, durable finish, but the speed and quality of this transformation depend on several important factors.

How Resin Curing Works

The curing process occurs as the molecules in resin and hardener link together, forming a strong three-dimensional network. This crosslinking provides the clear, hard surface that resin is prized for in coatings, crafts, and repairs. The heat generated during curing is a natural part of the reaction, but too much or too little heat can affect the final result.

Key Factors That Influence Resin Drying Time

Several elements impact how fast your resin cures and how good the finished product looks:

- Temperature: Most epoxy resins cure best between 75°F and 85°F (24°C to 30°C). Cooler temperatures slow down the reaction, while overheating can cause problems.

- Humidity: High humidity introduces moisture that can cause cloudiness or inhibit the curing process. Ideally, keep humidity below 60% to avoid such issues.

- Resin type: Different resins cure at varying speeds. For example, epoxy resins generally take longer than polyester or polyurethane types.

- Layer thickness: Thicker layers take longer to cure because the heat and chemical reaction must penetrate the entire depth. Thin layers will dry faster and reduce risk of imperfections.

- Mixing ratios: Precise measurement and mixing of resin to hardener are critical. An imbalance disrupts the chemical reaction, leading to sticky or uncured spots.

Why Rushing Resin Drying Can Harm Quality

It might be tempting to speed up curing by increasing heat excessively or adding extra hardener, but this can backfire. Common risks of rushing the process include:

- Yellowing: Excessive heat or rapid curing can cause discoloration, turning the clear resin yellow or amber.

- Stickiness and incomplete cure: Incorrect ratios or fast drying may leave the surface tacky and weak.

- Cracking and weak finishes: Overheating or uneven curing stresses the resin, resulting in cracks or reduced durability.

Taking your time and controlling these factors carefully is the best way to ensure a strong, clear, and lasting resin finish. Understanding the resin curing process lays the foundation for choosing the best methods to speed up resin drying safely without compromising quality.

Increase Workspace Temperature to Speed Up Resin Drying

One of the simplest and most effective ways to speed up resin curing is to raise the temperature in your workspace. Most epoxy resins cure best within an ideal range of 75 to 85°F (24 to 30°C). Staying within this temperature window helps the chemical reaction between the resin and hardener move along faster without compromising quality.

Use Safe Heat Sources

To maintain a consistent warm environment, consider these heat sources:

- Space heaters – Easy to position close by but keep them at a safe distance to avoid hot spots.

- Heat lamps – Provide targeted warmth, especially useful for smaller resin projects.

- Warm water baths – Placing resin bottles in warm water before mixing can slightly raise the resin’s temperature, speeding up curing time.

Avoid Overheating to Prevent Damage

Be cautious not to overheat resin as temperatures above 90°F (32°C) can cause problems such as:

- Cracking due to too rapid curing and internal stress

- Yellowing from heat-induced chemical changes

- Uneven curing that ruins the finish and durability

Always monitor your workspace temperature carefully to balance speeding up resin drying with maintaining a high-quality, clear finish. Using thermostats or digital thermometers can help keep your environment controlled and consistent.

Choose Fast-Curing Resin to Speed Up Resin Drying

One of the simplest ways to speed up resin drying is to use a fast-curing epoxy resin designed for quicker cure times. For example, Blissam’s Fast-Cure Epoxy Resin is engineered to harden faster than standard resins without sacrificing strength or clarity. This type of resin lets you complete projects faster while maintaining a durable, crystal-clear finish.

Comparing Resin Types for Curing Speed

Understanding the differences between resin types can help you pick the best option for your timeline:

- Epoxy Resin: Most versatile, generally cures slower than polyester but offers excellent clarity and durability. Fast-cure formulations like Blissam’s reduce curing time substantially.

- Polyester Resin: Cures faster but is often less clear and produces stronger odors. It’s not the best choice for projects requiring a flawless, glass-like finish.

- Polyurethane Resin: Typically cures quickly and offers good flexibility but might yellow over time and can be tricky to work with on delicate applications.

Why Choose Blissam’s Fast-Curing Resins

Blissam’s fast-curing epoxy resins stand out because they combine speed with quality. Key benefits include:

- Low odor – safer and more pleasant to work with indoors.

- UV resistance – prevents yellowing, keeping your work crystal clear.

- Easy 1:1 mixing ratio – reduces mistakes, promotes even curing.

- Durable finish – strong, long-lasting surfaces suited for many applications.

Using a fast-curing resin like Blissam’s lets you reduce resin curing time without the common quality risks of rushing standard resins. This means quicker project turnover and better results every time.

Apply Thin Layers to Speed Up Resin Curing

One of the simplest and most effective ways to speed up resin drying is to apply thin layers. Thinner layers cure faster because there’s less mass for heat to penetrate during the exothermic curing process. This helps the resin set quicker and reduces the chance of uneven curing or sticky spots.

Why Thin Layers Cure Faster

- Less volume means faster heat dissipation, so the resin reaches the right temperature sooner.

- Reduced curing time helps avoid issues like yellowing or cracking caused by overheating thick layers.

- Better control over the finish ensures a stronger, clearer coat every time.

Use a Layering Method for Better Results

Instead of pouring all the resin at once, pour multiple thin layers, letting each layer partially cure before adding the next. This staged approach allows you to:

- Keep the resin curing evenly across the project

- Minimize trapped air bubbles for a smooth, clear surface

- Build up thicker coatings without extending overall cure time too long

Tips for Even Bubble-Free Layers

- Mix resin thoroughly but gently to avoid introducing bubbles from vigorous stirring.

- Use a plastic spreader or brush to level the layer immediately after pouring.

- Apply heat gently with a butane torch or heat gun (on low setting) to pop surface bubbles quickly—avoid overheating.

- Work in a dust-free, well-ventilated space to prevent contaminants from settling on wet resin.

Applying thin layers not only makes your resin cure faster but also helps achieve a professional, clear, and durable finish every time. It’s a must-try for anyone looking to reduce resin curing time while maintaining quality.

Use UV Resin to Speed Up Resin Drying for Small Projects

When you want to speed up resin curing, especially for small projects, UV resin is a great choice. Unlike traditional epoxy, UV resin cures in just minutes under a UV lamp with a power of 4 watts or higher. This quick-drying resin technique lets you finish projects fast without waiting hours or days.

Best Uses for UV Resin

- Ideal for small items like jewelry, charms, and tiny decorative pieces

- Perfect for thin coatings or surface layers on crafts needing a crystal-clear finish

- Works well for quick fixes or when you need to add a durable, glossy top coat

Limitations of UV Resin for Fast Curing

- Not suitable for thick pours or large-scale projects; UV light can’t cure deep layers well

- Requires access to a proper UV lamp; sunlight may be inconsistent

- Less flexible than some epoxies, so it’s best for pieces that won’t be heavily handled

Using UV resin is a solid strategy for cutting down curing time in small-scale work. If you’re crafting jewelry or thin coatings, this is one of the fastest options to get a fully hardened, clear, and durable finish without sacrificing quality.

Control Humidity to Speed Up Resin Drying and Improve Curing

Humidity plays a crucial role in how your resin cures. For most epoxy resins, keeping the humidity below 60% is ideal to avoid common curing issues like stickiness, cloudiness, or extended drying times.

Why Humidity Matters for Resin Curing

High moisture levels in the air can interfere with the chemical reaction between resin and hardener, slowing down the curing process. It may also cause problems such as:

- Uneven curing

- Surface tackiness

- White or cloudy spots on the finish

How to Control Humidity for Faster Resin Drying

Here are easy, practical steps to keep humidity in check:

- Use a dehumidifier: This is the most straightforward way to reduce moisture, especially in damp workspaces.

- Work in a well-ventilated area: Circulating air helps lower humidity and speeds evaporation of any trapped moisture.

- Avoid working outside on humid days: Outdoor conditions can vary, and high humidity can slow curing dramatically.

- Use air conditioners or heaters as needed: They help maintain consistent temperature and humidity levels.

By maintaining a controlled environment with optimal humidity below 60%, you can significantly reduce resin curing time and ensure a stronger, clearer, and smoother finish.

For more tips on resin handling and troubleshooting, check out our guide on what is cured resin to better understand the curing process and factors involved.

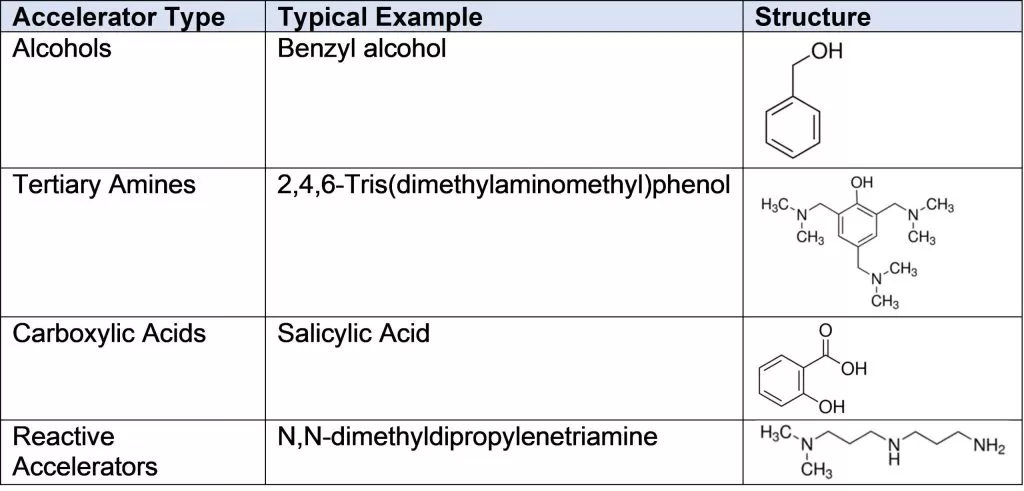

Consider Resin Accelerators to Speed Up Resin Drying Safely

Resin accelerators are special additives designed to reduce the epoxy resin curing time by speeding up the chemical reaction between resin and hardener. When used correctly, they can help you get faster results without compromising the quality of your finish — perfect for shrinking project timelines on a tight schedule.

How Resin Accelerators Work

- They boost the hardening process, making resin dry quicker than usual.

- Usually added in small amounts to epoxy, they create a faster cure without changing the mix ratio drastically.

- Popular in fast-curing epoxy resin formulations like Blissam’s products, ensuring compatibility and performance.

Risks of Overusing Resin Accelerators

While accelerators can help speed up resin drying, overdoing it can lead to problems such as:

- Yellowing or discoloration of the resin finish due to uneven curing.

- Sticky or soft spots where resin doesn’t fully harden.

- Cracks or brittleness caused by too rapid curing, which doesn’t allow the resin to settle properly.

Best Practices for Using Resin Accelerators

- Always follow manufacturer guidelines strictly, especially with brands like Blissam, which offer recommended accelerator types and compatible dosages.

- Add accelerators sparingly; too much can cause uneven curing and quality issues.

- Test accelerators on a small sample before applying to your final project.

- Combine accelerators with other curing tips like temperature control and layering for balanced speeding up.

Using resin accelerators carefully lets you reduce resin curing time without risking your project’s durability or appearance. For reliable, fast-curing options, check out Blissam’s low-odor, UV-resistant epoxy resins and their compatible accelerators—designed to get your resin projects done right and quicker.

Proven Methods to Speed Up Resin Curing Advanced Tools for Professionals

For those looking to speed up resin drying significantly, investing in advanced resin curing tools can make a big difference. These tools provide controlled environments that optimize the curing process, producing consistent, high-quality results in a fraction of the usual time.

Resin Curing Machines for Fast Results

Resin curing machines are designed to accelerate the curing of epoxy and other fast-curing resins. They typically reduce curing time to 2–3 hours, compared to the standard 24–48 hours needed at room temperature. These machines apply precise heat and sometimes pressure, enhancing the exothermic reaction between resin and hardener for a quicker, stronger cure.

- Consistent curing temperature: Ensures even hardness and reduces defects like bubbles or yellowing

- Rapid turnaround: Ideal for professional settings or high-volume production where time is crucial

Epoxy Curing Blankets and Craft Ovens

For those who want a more flexible setup, epoxy curing blankets and craft ovens are excellent options. These provide steady, gentle heat over the curing area, maintaining an optimal temperature range (around 75–85°F or 24–30°C) to speed up curing without risking damage.

- Curing blankets: Easy to wrap around molds or projects, keeping heat consistent

- Craft ovens: Offer controlled temperature settings for curing multiple pieces simultaneously

- Benefit: Improved resin clarity, reduced yellowing, and enhanced hardness

Cost vs Benefit Analysis for Hobbyists and Professionals

While these advanced tools speed up resin curing, assessing their value depends on your needs:

| User Type | Pros | Cons | Recommendation |

|---|---|---|---|

| Hobbyists | Faster curing, better results | High upfront cost | Use only if frequently curing large projects or selling finished items |

| Professionals | Increased productivity and quality | Investment justified by scale | Essential for businesses with consistent demand and deadlines |

If you’re an occasional user, standard temperature control methods may suffice. But for frequent or commercial use, investing in professional curing machines or ovens pays off by cutting down production time and improving the final finish.

For more on how resin cures and the importance of controlled conditions, check out our detailed guide on what is cured resin.

Common Mistakes to Avoid When Trying to Speed Up Resin Drying

Speeding up resin drying is tempting, but certain mistakes can harm your final project. Here’s what to watch out for:

Adding Extra Hardener

- Don’t disrupt the mixing ratio. Most epoxy resins, including fast-curing ones, need a precise 1:1 ratio of resin to hardener.

- Adding extra hardener throws off this balance, often causing sticky spots, uncured areas, or weak finishes.

- Always measure carefully using a digital scale or precise measuring tools.

Using a Hairdryer to Speed Curing

- Hairdryers seem like a quick fix but can cause uneven heating, leading to surface bubbles, rippling, or even partial curing.

- Hot air can disturb the resin’s surface tension, causing imperfections that ruin the clarity or smoothness.

- Instead, opt for steady ambient heat like a space heater or warm bath for bottles.

Overheating Resin

- Excess heat may feel like a shortcut but it comes with risks:

- Cracking or warping as the resin cures too fast.

- Yellowing or discoloration, especially in clear resins.

- In extreme cases, fire hazards if using unsafe heat sources.

- Stick to recommended temperature ranges (75–85°F or 24–30°C) for best results.

Ignoring Manufacturer Instructions

- Each resin product is formulated differently; ignoring instructions can lead to curing failures.

- Precise timing, mixing ratios, and conditions matter a lot—especially with fast-curing or specialty resins like Blissam’s.

- Follow guidelines for storage, application layers, and curing environments to ensure consistent quality.

Avoiding these common pitfalls helps you get a smooth, durable finish without sacrificing quality in your efforts to speed up resin curing.

Safety Tips for Faster Resin Curing and Handling

When you’re working to speed up resin drying, safety should never take a back seat. Fast curing often involves using heat or other tools that can pose risks if not managed properly. Here’s how to stay safe while getting your resin to cure faster:

Work in a Well-Ventilated Area

Resin releases fumes during curing, especially when heat is applied. Always work in a space with good airflow — open windows, fans, or even a dedicated ventilation system can help reduce inhalation risks. This is vital not only for your health but also for maintaining a safe workspace.

Wear Proper Protective Gear

Handling resin and heat sources exposes you to chemical and burn risks. Wear nitrile gloves to protect your skin from resin contact, and eye protection such as safety goggles to prevent splashes. This also goes for any accelerants or additives you might use to speed up curing.

Monitor Heat Sources Closely

Using heat lamps, space heaters, or curing blankets can accelerate resin curing but comes with fire risks.

- Never leave heating tools unattended.

- Keep heat sources away from flammable materials.

- Use timers or thermostats to avoid overheating, which can cause cracking, yellowing, or even fire hazards.

Proper Disposal of Resin Waste

Resin-contaminated water or cleaning materials can harm the environment.

- Dispose of all resin waste according to local hazardous waste regulations.

- Avoid pouring resin residues down the drain.

- Use absorbent materials for spills and dispose of them responsibly to minimize environmental impact.

Following these safety steps ensures that you can speed up resin curing without compromising your health, workspace safety, or the environment. For more tips on resin handling and cleanup, check out our guide on how to get resin off hands.

Why Choose Blissam for Faster Resin Curing Fast Curing Epoxy Resin Solutions

When it comes to speeding up your resin drying without sacrificing quality, Blissam’s fast-curing epoxy resin stands out as a top choice. Designed with the needs of both hobbyists and professionals in mind, Blissam offers low-odor, UV-resistant epoxy that cures quickly while maintaining a crystal-clear finish. This ensures your projects look flawless and durable over time, resistant to yellowing and cracking.

Easy 1 to 1 Mixing Ratio for Consistent Results

One of the biggest challenges in resin curing is getting the mix ratio right. Blissam simplifies this by providing an easy-to-use 1:1 mixing ratio, which reduces errors, speeds up preparation, and guarantees even curing every time. This straightforward formula helps you save time and avoid sticky or uneven spots.

Fast Curing Resin and Accelerator Options

Blissam also offers specialized resin accelerators that work seamlessly with their fast-curing epoxy systems. These additives are designed to safely reduce curing times further without compromising the finish quality, giving you more control over your working time and production schedules. You can explore these products here.

Proven by Customers and Case Studies

Many users across the United States trust Blissam for projects that require quick-drying resin without the usual headaches. From art pieces to industrial applications, customer testimonials highlight consistent, professional-grade results and excellent clarity. Their success stories demonstrate how Blissam’s products deliver reliable fast curing while keeping your resin projects looking sharp.

For more information on how to get the best results with resin curing, check out our detailed guide on what is cured resin.

Choose Blissam for fast, reliable resin curing that fits your timeline without cutting corners on quality or finish.