Are you battling foam issues in your oil and gas operations? Choosing the right defoamer can transform your processes, boosting efficiency and slashing costs.

As an industry leader, Blissam understands the unique challenges of foam control in drilling, refining, and gas processing. With years of expertise, we’re here to share proven insights and solutions tailored for the oil and gas sector.

In this guide, you’ll discover how defoamers work, their critical applications, and why Blissam’s antifoaming agents are trusted by top producers worldwide.

Ready to optimize your operations? Let’s dive in!

What Are Defoamers in Oil and Gas and How Do They Work

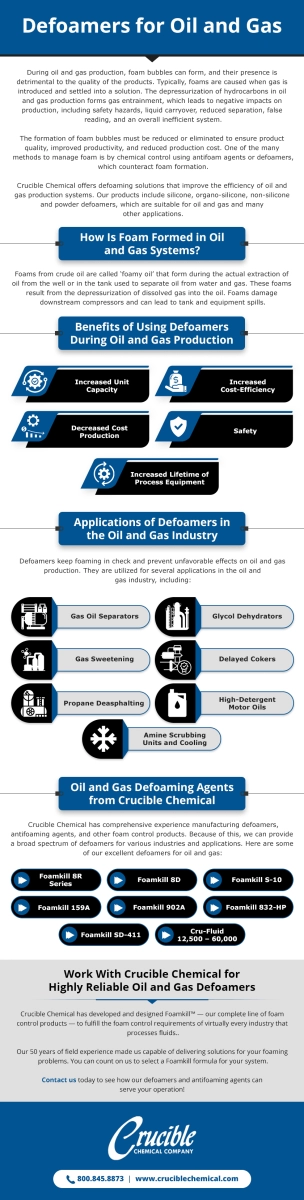

Foaming is a common hassle in oil and gas operations, affecting processes from drilling to refining. Defoamers, also known as antifoaming agents, are chemical additives designed to reduce or completely prevent foam formation in these industrial systems.

What Are Defoamers

In simple terms, defoamers are specialized chemicals added to fluids used in oil and gas production that break down foam or keep it from forming in the first place. They target the root cause — the gas bubbles trapped in liquids that create stubborn, stable foam layers.

How Defomers Work

Defoamers work by disrupting the gas bubbles that combine to form foam. They spread quickly on the surface of these bubbles, causing them to collapse and break apart. This stops foam from stabilizing and growing, helping maintain smoother operations.

- Reduce foam stability by thinning the liquid films around bubbles

- Break bubble surfaces to release trapped gas quickly

- Prevent reformation by altering surface tension in fluids

Types of Defoamers Used in Oil and Gas

Depending on the specific application and fluid system, defoamers come in different forms:

- Silicone-based defoamers: Very effective and widely used for their fast action and long-lasting foam control. Common in refining and gas processing.

- Mineral oil-based defoamers: Oil-compatible and good for upstream uses like drilling fluids and cementing.

- Polymer-based defoamers: Versatile in specialty applications where tailored formulations are needed.

Why Foam Is a Problem in Oil and Gas

Foam might look harmless, but it causes real operational headaches:

- Equipment damage and wear: Foam can cause pumps and separators to run inefficiently or get damaged.

- Reduced production efficiency: Foam leads to inaccurate flow measurements, slower processing, and potential shutdowns.

- Lower product quality: Foam interferes with refining, gas-liquid separation, and wastewater treatment, risking contamination.

- Safety hazards: Excessive foam can trigger overflows or pressure build-up, which are dangerous in high-pressure oilfield environments.

In short, tackling foam effectively with the right defoamer is critical to keep oil and gas production safe, efficient, and cost-effective.

Applications of Defoamers in Oil and Gas

Defoamers play a crucial role across the oil and gas industry, helping maintain smooth operations by controlling foam formation at every stage. From upstream activities to downstream processing, using the right antifoaming agents oil and gas ensures better productivity and less downtime.

Upstream Foam Control

In upstream operations, foam control in drilling fluids is vital. Drilling fluids often generate foam that can slow down the process or cause equipment damage. Defoamers are also essential during cementing and well completion, where foam can interfere with fluid flow and compromise well integrity. Using industrial defoamer solutions here improves operation safety and effectiveness.

Midstream Foam Prevention

During the midstream phase, foam formation can occur during transportation and gas-liquid separation. Foam in pipelines or separators can reduce throughput and cause pressure build-ups. Applying the right chemical additives for oil and gas prevents foam, ensuring steady flow rates and safer conditions.

Downstream Foam Management

At downstream facilities, defoamers are critical in refining processes, wastewater treatment, and gas processing. Foam can disrupt the refining process, reduce product quality, and complicate wastewater management. Using silicone defoamers for refining or tailored non-silicone options helps maintain clean operations and regulatory compliance.

Real-World Impact of Defoamers

In practice, defoamers boost productivity by preventing costly delays due to foam-related equipment fouling or shutdowns. Many operators have experienced reduced downtime, lower maintenance expenses, and improved process stability thanks to well-applied foam control solutions. In the U.S., where oil and gas production demands efficiency and reliability, defoamers are a key part of the chemical strategy.

In

- Upstream: Foam control in drilling fluids, cementing, and well completion

- Midstream: Foam prevention during transportation and separation

- Downstream: Foam suppression in refining, wastewater, and gas processing

- Results: Increased productivity, reduced downtime, and, cleaner operations

Deploying effective defoamer solutions tailored to each phase helps operators meet production goals and maintain a competitive edge in the U.S. oil and gas market.

Benefits of Using Defoamers in Oil and Gas Operations

Using defoamers in oil and gas brings several critical advantages that directly impact your operations and bottom line. Here’s how these chemical additives improve your processes and safety:

Enhanced Operational Efficiency and Equipment Longevity

Defoamers reduce foam buildup, which otherwise slows down processing and puts extra strain on equipment. By controlling foam, you:

- Maintain smoother fluid flow in drilling, transport, and refining stages

- Minimize interruptions caused by foam-related equipment fouling

- Cut down on frequent shutdowns and unplanned maintenance

This leads toless equipment wear**, extending machinery life and reducing downtime.

Significant Cost Savings Through Optimized Processes

Foam interferes with your production efficiency, meaning you spend more time and energy fixing issues or slowing down operations. With effective defoamer use, you can:

- Increase throughput without the drag of foam-related setbacks

- Lower chemical and cleaning costs by preventing foam-related contamination

- Optimize use of drilling fluids, cementing, and gas processing chemicals

These improvements translate into higher cost-efficiency, giving you better returns on your investment in oil and gas production chemicals.

Environmental Compliance and Waste Reduction

Many regulations demand strict control of wastewater discharge and emissions in oil and gas operations. Defoamers help you:

- Minimize foam-related waste and overflow incidents

- Ensure smoother separation of gases and liquids, reducing chemical carryover

- Meet environmental standards without costly corrective measures

Choosing eco-friendly defoamers supports both compliance and sustainability goals, which are increasingly important in U.S. energy markets.

Improved Safety in High-Pressure and Complex Systems

Foam can cause pressure spikes, liquid carryover, and equipment malfunctions, risking operator safety and causing operational hazards. Effective foam control:

- Prevents dangerous surges and blockages in pipelines and separators

- Reduces chances of overflows or gas leaks triggered by trapped foam

- Supports safer well completion, drilling fluids handling, and refinery processes

By preventing foam-related hazards, defoamers play a key role in maintaining a safe work environment across oilfield and gas processing operations.

investing in industrial defoamer solutions is essential for maintaining efficient, cost-effective, and safe oil and gas production. They optimize your entire value chain from upstream drilling to downstream refining, making them a must-have for U.S.-based oil and gas operations aiming for reliability and compliance.

Why Choose Blissam Defoamers for Oil and Gas Operations

When it comes to tackling foam challenges in oil and gas, Blissam offers a broad range of high-quality defoamers designed specifically for the industry. Whether you need silicone or non-silicone defoamers, our products are tailored to meet the unique demands of upstream, midstream, and downstream processes.

Comprehensive Product Range for Oil and Gas Applications

- Silicone-based defoamers excel in rapid foam knockdown and long-lasting performance, ideal for refining and gas processing.

- Non-silicone defoamers, including mineral oil and polymer-based options, provide versatile solutions for drilling fluids, cementing, and wastewater treatment.

- All Blissam defoamers are formulated to address specific foam types encountered in oilfield operations and industrial defoamer solutions.

What Sets Blissam Apart

- High-performance formulations that ensure fast foam suppression and durability under tough conditions like high pressure and extreme temperatures.

- Customizable solutions tailored to your facility’s exact processes and fluid compositions.

- A reliable supply chain focused on timely delivery and consistent product quality across the United States.

Proven Results in Real Oil and Gas Operations

We worked with a major shale gas producer struggling with foam issues in well completion fluids that reduced efficiency and increased downtime. By applying Blissam’s custom silicone defoamer, they experienced:

- A 50% reduction in foam-related delays

- Improved equipment reliability

- Significant operational cost savings

This case underscores how our defoamers can directly improve production and reduce maintenance.

Commitment to Sustainable Foam Control

Blissam also prioritizes environmental responsibility. We offer eco-friendly defoamer options formulated to minimize waste and comply with strict US environmental regulations. These options help oil and gas companies meet sustainability goals without compromising foam control effectiveness.

Choosing Blissam means partnering with a trusted chemicals manufacturer who understands the US oil and gas market and delivers effective, safe, and sustainable defoaming solutions for every stage of your operations.

How to Select the Right Defoamer Oil and Gas Applications

Choosing the right defoamer for oil and gas operations is crucial to effective foam control and smooth production. Several factors come into play to ensure you get the best-fit defoamer that meets your specific needs.

Key Factors to Consider

- Process Type: Identify where foam is occurring—drilling fluids, gas processing, refining, or wastewater treatment. Different stages require tailored defoamer formulations.

- Operating Conditions: Temperature and pressure vary greatly across upstream, midstream, and downstream operations. Your defoamer must withstand these conditions without loss of performance.

- Fluid Composition: The chemical makeup of the fluid, whether oily, aqueous, or a complex mixture, impacts the defoamer’s effectiveness. Compatibility is essential to avoid unwanted reactions.

- Foam Type and Severity: Determine whether you face stubborn, stable foam or occasional, light foaming. That will influence defoamer concentration and type.

Silicone vs Non-Silicone Defoamers

Silicone-Based Defoamers

- Excellent for quick and strong foam suppression.

- Ideal for high-temperature refining and gas processing.

- May separate in oily or heavy hydrocarbon environments.

Non-Silicone Defoamers (Mineral Oil & Polymer-Based)

- Better compatibility with hydrocarbon-rich fluids and sensitive processes.

- Generally more stable in aggressive chemical conditions.

- Slightly slower foam knockdown but more versatile.

Knowing these differences helps you balance performance, cost, and process needs.

How Blissam Helps with Defoamer Selection

At Blissam, we understand the challenges of foam control in oil and gas. Our experts work closely with you to:

- Assess your process parameters and foam issues

- Recommend tailored defoamer formulations—silicone or non-silicone

- Provide lab testing support to confirm effectiveness

- Ensure supply chain reliability for uninterrupted operations

Defoamer Selection Checklist

Ask your supplier these key questions before deciding:

- Is the defoamer compatible with my process fluids and conditions?

- Can it operate effectively at my system’s temperature and pressure?

- What is the expected dosage and impact on process efficiency?

- Are there any environmental or regulatory compliance benefits?

- How reliable is the supplier’s technical support and logistics?

For more details on how defoamers work and their applications, you can also check our pages on What is Defoamer and How Defoamer Works.

Making the right choice upfront saves time, cuts costs, and safeguards your equipment and product quality throughout your oil and gas operations.

Industry Trends and Innovations in Defoamer Technology for Oil and Gas

Advances in Eco-Friendly and High-Performance Defoamers

The oil and gas sector is seeing a strong shift toward eco-friendly defoamers that deliver high efficiency without harming the environment. New formulas now use biodegradable ingredients and reduced volatile organic compounds (VOCs), making them safer for both operations and surrounding ecosystems. These modern antifoaming agents oil and gas applications ensure compliance with evolving environmental standards while maintaining superior foam control, especially in sensitive areas like wastewater treatment and gas processing.

Role of Defoamers in Meeting Stricter Environmental Regulations

With increasing regulations targeting emissions, waste, and chemical use, defoamers are more critical than ever for environmentally responsible oil and gas production chemicals. Effective foam suppression reduces the need for frequent chemical dosing and minimizes process disruptions, which directly supports cleaner operations. This aligns with compliance goals by helping companies meet wastewater discharge limits and reduce chemical footprints without sacrificing operational efficiency.

Emerging Applications in Unconventional Oil and Gas

As the industry evolves, so do foam control needs—with growing interest in unconventional resources such as shale gas, LNG, and other tight formations. These operations involve complex fluids and conditions where foam can severely impact equipment and production. Defoamers designed for foam control in drilling and well completion now focus on handling high pressures, variable temperatures, and diverse fluid chemistries found in these environments. This drives demand for customized solutions that can adapt to the challenges of unconventional oil and gas.

Blissam’s Commitment to Innovation

At Blissam, we stay ahead by continuously investing in R&D for defoamer technology. Our goal is to develop next-gen defoamers that combine high-performance foam suppression with eco-conscious formulas tailored for U.S. oil and gas operations. Through ongoing research, we offer products that meet emerging demands, support stricter environmental regulations, and handle the specialized needs of unconventional resource plays. Our innovations ensure your operations run smoothly and sustainably.

For more details about how defoamers work and their applications, visit our pages on How Defoamer Works and What Is Defoamer.