What is Sodium Lauryl Polyoxyethylene Ether Sulfate

Sodium Lauryl Polyoxyethylene Ether Sulfate, identified by CAS number 9004-82-4, is a widely used anionic surfactant in personal care and cleaning products. Its molecular formula is generally represented as (C2H4O)nC12H26O4S.Na, where the “n” denotes the variable number of ethylene oxide units introduced through a process called ethoxylation.

Chemical Identity and Structure

- CAS 9004-82-4 confirms the chemical’s unique identity for regulatory and sourcing purposes.

- The molecule combines a hydrophobic lauryl (C12) alkyl chain with a hydrophilic polyoxyethylene (ethylene oxide) chain and a sulfate group, making it an effective surfactant.

- The ethoxylation process attaches ethylene oxide units to sodium lauryl sulfate, creating a softer, more water-soluble, and less irritating surfactant compared to unmodified forms.

Anionic Surfactant Properties and Ethoxylation

- As an anionic surfactant, Sodium Lauryl Polyoxyethylene Ether Sulfate carries a negative charge on its sulfate group, which helps it to reduce surface tension and interact with oils and dirt.

- The ethoxylation step improves its performance by increasing solubility and reducing irritation, making it gentler for skin and eyes while maintaining strong cleansing and foaming properties.

- This process also enhances its compatibility with hard water and other formulation ingredients.

Comparison with Sodium Lauryl Sulfate (SLS)

- Unlike Sodium Lauryl Sulfate (SLS), which is non-ethoxylated and often harsher, SLES (Sodium Lauryl Polyoxyethylene Ether Sulfate) is known for having better skin tolerance and lower irritation.

- Both are strong detergent surfactants and excellent foaming agents, but SLES is preferred in formulations where mildness and biodegradability are important.

- SLES is often labeled as Sodium Laureth Sulfate or Sodium Lauryl Ether Sulfate (SLES 70%) in the market, reflecting its ethoxylate content and standard purity.

By choosing Sodium Lauryl Polyoxyethylene Ether Sulfate, formulators gain a highly effective, mild, and biodegradable surfactant trusted across cosmetics, detergents, and industrial applications.

Key Properties and Benefits of Sodium Lauryl Polyoxyethylene Ether Sulfate

Sodium Lauryl Polyoxyethylene Ether Sulfate (SLES) is prized for its excellent chemical properties that make it a go-to anionic surfactant in many formulations. It offers:

- Superior emulsification – SLES effectively blends oil and water, ensuring smooth and stable mixtures.

- Strong dispersion ability – It distributes particles evenly in solutions, which helps prevent clumping.

- Outstanding wetting power – This allows liquids to spread quickly and thoroughly over surfaces, improving cleaning efficiency.

- Rich foaming capabilities – SLES creates abundant, stable foam that boosts the sensory experience in personal care and cleaning products.

Performance Benefits

What sets SLES apart from similar surfactants like Sodium Lauryl Sulfate (SLS) is its high biodegradability, which aligns well with eco-conscious regulations and consumer demand in the U.S. market. It also shows:

- Low skin and eye irritation compared to SLS, making it gentler for use in shampoos, body washes, and toothpaste.

- Resistance to hard water – SLES maintains its performance even in water with high mineral content, important for consistent cleaning results across different regions.

Versatility in Formulation

SLES stands out due to its broad compatibility with other ingredients, allowing it to be easily integrated into complex formulas without destabilizing them. Additionally, it serves as an effective thickening agent, enhancing texture and viscosity in various products.

These key properties make Sodium Lauryl Polyoxyethylene Ether Sulfate a reliable, efficient, and eco-friendly choice for manufacturers targeting both personal care and household cleaning applications in the U.S. market.

Applications of Sodium Lauryl Polyoxyethylene Ether Sulfate

Sodium Lauryl Polyoxyethylene Ether Sulfate (CAS 9004-82-4), widely known as SLES, is a versatile anionic surfactant used across a range of industries thanks to its excellent cleansing, foaming, and emulsifying properties.

Personal Care Products

SLES is a go-to ingredient in many personal care formulations. It’s commonly found in:

- Shampoos and body washes for effective cleansing and rich foam

- Soaps and toothpaste, providing gentle yet thorough cleaning

- Its low irritation profile makes it suitable for everyday use in products designed for sensitive skin

Household Detergents

In household cleaning, Sodium Lauryl Polyoxyethylene Ether Sulfate shines as a powerful surfactant that enhances the cleaning power of:

- Dishwashing liquids for grease removal and foam stability

- Laundry detergents, improving dirt and stain removal while maintaining fabric care

- Surface cleaners for thorough yet gentle cleaning on various surfaces

Industrial Uses

Beyond consumer goods, SLES plays a vital role in industrial applications, where consistent performance under demanding conditions is key:

- Textile processing to aid in washing and dyeing steps

- Leather treatment, improving cleaning and conditioning processes

- Components in petroleum formulations that require emulsification and dispersion

- Herbicide formulations, helping active ingredients disperse evenly for effective application

Research Applications

SLES is also valued in scientific research and development due to its reliable surfactant performance:

- Used in proteomics for protein isolation and analysis

- Applied in material science studies requiring controlled emulsification

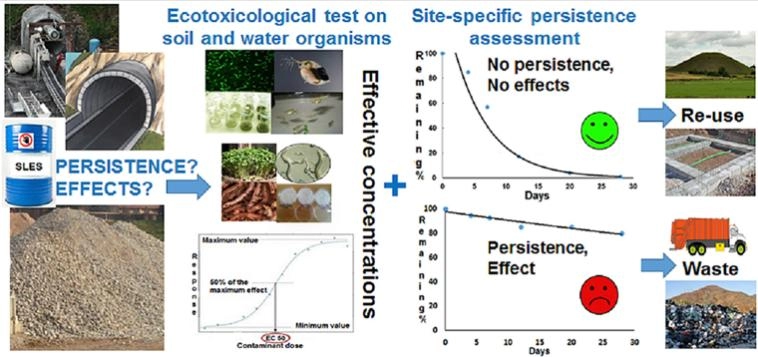

- Employed in environmental remediation to help break down pollutants and assist in cleanup efforts

In each of these applications, the biodegradability, low irritation, and compatibility of Sodium Lauryl Polyoxyethylene Ether Sulfate make it a preferred choice for formulators and manufacturers focused on delivering effective, safe, and sustainable products.

Why Choose Blissam’s Sodium Lauryl Polyoxyethylene Ether Sulfate

When it comes to Sodium Lauryl Polyoxyethylene Ether Sulfate (CAS 9004-82-4), Blissam stands out as a trusted SLES supplier in the U.S. Here’s why our product is the preferred choice for personal care, household, and industrial applications:

Quality Assurance Meeting Global Standards

- ISO 9001:2015 certified manufacturing ensures consistent product quality.

- Fully REACH compliant, meeting international safety and environmental regulations.

- Our Sodium Lauryl Polyoxyethylene Ether Sulfate undergoes strict testing to guarantee purity and performance.

Custom Solutions for Different Needs

- Available in multiple concentrations, such as SLES 70%, to match your formulation requirements.

- Offered in bulk packaging options tailored to your business scale, reducing handling and transport costs.

- Flexible supply supports a range of applications, from shampoos and detergents to industrial cleaners.

Reliable Supply Chain and Competitive Pricing

- Globally distributed with fast delivery across the United States, ensuring your production runs smoothly.

- We maintain strong relationships with raw material sources like palm kernel and coconut oil to keep prices competitive.

- Your orders come with prompt service and logistical support to avoid delays.

Commitment to Sustainability and Eco-Friendly Production

- Our Sodium Lauryl Polyoxyethylene Ether Sulfate is highly biodegradable, aligning with growing environmental concerns.

- Made using green manufacturing processes to minimize waste and reduce carbon footprint.

- We help brands meet sustainability goals without compromising product effectiveness.

Choosing Blissam means you get a high-quality, reliable, and sustainable anionic surfactant that suits U.S. market demands—backed by a supplier that prioritizes both performance and responsibility.

Safety and Handling of Sodium Lauryl Polyoxyethylene Ether Sulfate

When working with Sodium Lauryl Polyoxyethylene Ether Sulfate (SLES CAS 9004-82-4), safety is key. This anionic surfactant is widely used in personal care and cleaning products due to its effective cleansing and foaming properties, but knowing how to handle it properly ensures safe use and storage.

Safety Overview and Regulatory Compliance

- Low Irritation Risk: SLES is generally considered safe for consumer products. It meets regulatory standards set by agencies such as the US FDA and EPA, showing low skin and eye irritation when used at recommended concentrations.

- Approved for Personal Care: Its safety profile supports use in shampoos, body washes, and toothpaste, where it provides excellent foaming and cleaning without harshness.

Potential Risks and Precautions

- High Concentration Caution: At high concentrations or prolonged exposure, SLES can cause moderate skin or eye irritation. This is important for workers handling raw materials or concentrated products.

- Dioxane Contamination: Trace amounts of 1,4-dioxane, a byproduct from the ethoxylation process, may be present. Though generally low, it’s essential to source SLES from reputable suppliers who control this impurity to stay below safety thresholds.

Proper Handling and Storage Guidelines

- Storage Conditions: Keep SLES in cool, dry, and sealed containers to prevent contamination and degradation.

- Avoid Reactive Chemicals: Store away from strong oxidizers and acids which can destabilize the product or cause hazardous reactions.

- Use Personal Protective Equipment (PPE): When handling bulk or concentrated SLES, wear gloves and eye protection to minimize direct contact.

By following these safety and handling practices, Sodium Lauryl Polyoxyethylene Ether Sulfate can be used effectively in various applications across personal care, household, and industrial products without compromising safety.

How Sodium Lauryl Polyoxyethylene Ether Sulfate Is Manufactured

Manufacturing Sodium Lauryl Polyoxyethylene Ether Sulfate (SLES CAS 9004-82-4) involves several precise steps to ensure high quality and consistent performance. Here’s a straightforward look at the process:

Step by Step Manufacturing Process

- Ethoxylation of Lauryl Alcohol

- The process starts with ethoxylation where lauryl alcohol reacts with ethylene oxide. This adds polyoxyethylene groups (–(C2H4O)n–) making the molecule more water-soluble and less irritating compared to non-ethoxylated surfactants.

- Sulfation

- Next is the sulfation of the ethoxylated lauryl alcohol. This introduces the sulfate group (–OSO3Na), turning the compound into an anionic surfactant with excellent foaming and cleaning power.

- Neutralization

- The sulfated product is then neutralized, usually with sodium hydroxide, to create the sodium salt form that is stable and easy to use in formulations.

- Filtration and Purification

- Finally, the product undergoes filtration and purification to remove impurities, ensuring a clear, consistent, and high-performance surfactant.

Raw Materials Sourcing

- High-grade lauryl alcohol is sourced primarily from natural oils like palm kernel oil or coconut oil.

- Using renewable raw materials supports sustainability and meets increasing demand for eco-friendly chemicals in the U.S. market.

Blissam’s Efficient and Eco-Friendly Production

At Blissam, we combine cutting-edge technology with strict environmental standards to manufacture SLES responsibly:

- Our processes minimize waste and energy use to reduce our environmental footprint.

- We ensure compliance with REACH and ISO 9001:2015 standards, guaranteeing safe, high-quality surfactants.

- Blissam focuses on producing biodegradable and consumer-safe SLES that fits perfectly with today’s green industry trends.

By controlling every step — from sourcing sustainable raw materials to careful chemical processing — Blissam ensures its Sodium Lauryl Polyoxyethylene Ether Sulfate delivers consistent quality for shampoos, detergents, and industrial applications.

Frequently Asked Questions About Sodium Lauryl Polyoxyethylene Ether Sulfate SLES

What Is the Difference Between SLES and SLS

SLES (Sodium Lauryl Polyoxyethylene Ether Sulfate) and SLS (Sodium Lauryl Sulfate) are closely related anionic surfactants but differ in mildness and structure. SLES is ethoxylated, meaning it contains additional ethylene oxide units that make it gentler on skin and eyes, with lower irritation potential. SLS is more aggressive and can cause dryness or irritation, especially with repeated use. For personal care and household products, SLES is preferred for better skin compatibility and performance in foaming and cleansing.

Is SLES Safe for Skin and the Environment

Yes, Blissam’s SLES meets global safety standards and is widely recognized as safe for skin when used at recommended concentrations. It has high biodegradability, making it environmentally friendly. However, like any surfactant, it can cause irritation at high concentrations or with prolonged exposure. Our SLES complies with ISO 9001:2015 and REACH, ensuring strict safety and environmental care standards.

How Can I Request a Certificate of Analysis COA or Safety Data Sheet SDS

Blissam provides detailed Certificates of Analysis (COA) and Safety Data Sheets (SDS) for all our SLES products. To request these documents:

- Contact our customer support team via email or phone.

- Provide your purchase details or inquiry reference.

- We will promptly send certified documentation to support your compliance and quality assurance needs.

What Are the Available Concentrations of Blissam’s SLES

We offer Sodium Lauryl Polyoxyethylene Ether Sulfate in several concentrations to suit various applications:

- SLES 70% (commonly used in shampoos, detergents, and industrial formulations)

- Lower concentration grades for specialized uses or formulations requiring milder surfactants.

- Custom formulations can also be arranged upon request to meet your specific product requirements.

How to Order Bulk SLES from Blissam

Ordering bulk SLES from Blissam is straightforward:

- Reach out to our sales team with your volume requirements and product grade preference.

- We provide competitive pricing and flexible packaging options, including bulk drums and tanker shipments.

- Our reliable global supply chain ensures fast delivery, helping you keep your operations running smoothly.

- We also offer technical support to help you select the right SLES variant for your product formulation.

If you need an anionic surfactant supplier in the U.S. market that values quality, compliance, and service, Blissam is your go-to partner for Sodium Lauryl Polyoxyethylene Ether Sulfate CAS 9004-82-4.