Are you battling foam issues in your industrial processes? Uncontrolled foam can disrupt production, cause defects, and drive up costs. Understanding how defoamers work is the key to smoother operations and better results. At Blissam, we’ve spent years perfecting defoamer solutions to tackle these challenges across industries like paints, inks, and wastewater treatment. In this guide, you’ll discover the science behind defoamers, their real-world applications, and how to choose the right one for your needs. Let’s dive in and clear the foam!

What Are Defoamers

If you’ve ever dealt with unwanted foam in industrial processes, you know how frustrating it can be. Defoamers, also known as foam control additives or foam suppression chemicals, are specially designed agents that help eliminate and prevent foam formation efficiently.

Definition of Defoamers

A defoamer is a chemical agent added to liquids to break down existing foam and stop new foam from forming. Foam can cause issues such as reduced capacity, contamination, and poor surface quality in many manufacturing and treatment processes. Defoamers work by disrupting the stability of foam bubbles, allowing them to collapse quickly.

Difference Between Defoamers and Antifoams

People often use the terms defoamer and antifoam interchangeably, but there’s a subtle difference:

- Defoamers address foam that has already formed by quickly breaking bubbles.

- Antifoams prevent foam from developing in the first place.

In most industrial applications, the product combines both properties, but the term defoamer is more common for agents effective at knocking down foam quickly once it’s present.

Common Types of Defoamers

There are several types of defoamers tailored to different needs and processes, including:

-

Silicone-based defoamers

Known for strong performance and broad use in coatings, inks, and wastewater treatment.

-

Oil-based defoamers

Effective in processes where silicone incompatibility is an issue. Often used in food processing or where eco-friendliness is a concern.

-

Water-based defoamers

Ideal for water systems and situations requiring low toxicity and easy dispersion.

-

Powder defoamers

Applied in dry formulations, especially in ceramics and concrete.

Each type offers unique advantages depending on the foam characteristics, chemical environment, and industry requirements.

Understanding these basics clarifies how defoamers integrate into industrial solutions to maintain smooth, efficient processes without foam interference.

How Defoamers Work

Understanding how defoamers work helps in choosing the right foam control additives for your needs. At its core, a defoamer’s job is straightforward: break down foam and stop it from coming back. But the behind-the-scenes mechanism and components make this possible.

Mechanism Overview of Defoamers

Foam forms when bubbles get trapped in liquids and stabilized by surface-active agents (surfactants). Defoamers target these bubbles, causing them to collapse quickly. This is the basic principle behind the defoamer mechanism. They don’t just mask foam; they actively disrupt the bubble structure.

Key Components of Defoamers

- Hydrophobic oils or solids: These repel water, making the foam film unstable.

- Surfactants: Special additives that improve spreading and penetration into foam.

- Carrier fluids: This helps to disperse defoamer ingredients evenly throughout the liquid.

- In some cases, silicone-based defoamers are used for faster and more effective foam breakdown.

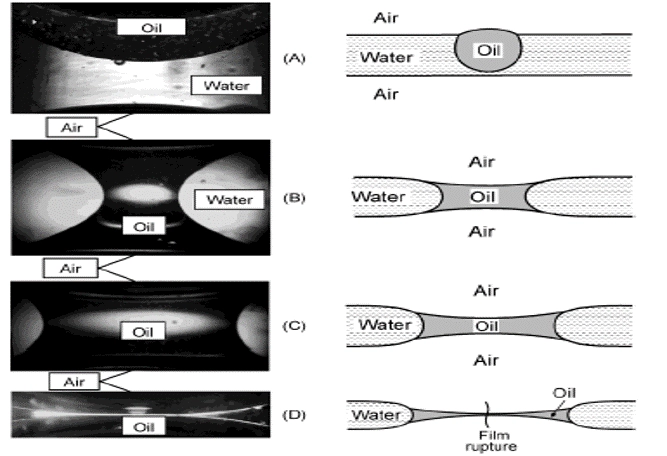

Process Breakdown of Foam Suppression

-

Spreading and Penetration

The defoamer quickly spreads on the foam surface, penetrating the thin liquid films around bubbles.

-

Film Rupture

The hydrophobic particles disrupt the foam film’s stability—the films get thinner and rupture.

-

Bubble Collapse

Once the film breaks, gas escapes and the foam disappears.

-

Prevention of Foam Reformation

Many industrial foam solutions also prevent new foam from forming by neutralizing surfactants or modifying surface tension.

In short, defoamers work by physically disrupting foam films, aided by their chemical makeup and design. This mechanism makes them essential in controlling foam in paints, inks, wastewater treatment, and other critical US industries where foam causes issues.

With the right defoamer, you can expect quick foam breakdown, long-lasting suppression, and fewer problems like pinholes or defects in your products.

Applications of Defoamers Across Industries

Defoamers play a vital role in many industries by controlling unwanted foam that can interfere with production and product quality. Here’s a quick look at where defoamers make a major difference and why their use is essential.

Defoamers in Paints and Coatings

In paints and coatings, foam control additives prevent bubbles that cause defects like pinholes or uneven surfaces. Foam can trap air, leading to:

- Poor film formation

- Reduced gloss or durability

- Surface imperfections during application

Using the right defoamer—often silicone-based defoamers—helps manufacturers deliver smooth, flawless coatings that meet stringent industry standards.

Defoamers in Inks

Foam suppression chemicals are crucial in ink production too. Foam forms during mixing and printing, which can cause:

- Inconsistent ink flow

- Blotchy prints

- Clogging in printers

Defoamers tailored for ink help maintain smooth printing operations and improve final print quality, reducing waste and downtime.

Wastewater Treatment Defomers

Managing foam in wastewater treatment systems is a big challenge. Foam builds up due to biological activity, affecting:

- Aeration efficiency

- Treatment performance

- Equipment lifespan

Industrial foam solutions designed specifically for wastewater treatment break down foam quickly so plants can operate safely and effectively without interruption.

Defoamers in Other Industries

Beyond coatings, inks, and wastewater, defoamers are essential in:

- Food and beverage processing: controlling foam during mixing and packaging

- Oil and gas: improving efficiency in drilling fluids and refining

- Pulp and paper: reducing foam during pulping and paper production

Each sector uses specialized defoamers designed for their unique processes and material compatibility.

Brand Tie-In and Why Choose Us

As a leading chemical manufacturer in the United States, we provide a wide range of defoamer products tailored to local industry demands. Our defoamers are:

- Highly effective and reliable

- Compatible with various formulations

- Available in eco-friendly options

- Supported by expert advice for the best foam control solutions

We understand the importance of precise foam management in your industry. Whether you need defoamers for coatings, inks, or wastewater treatment, we have solutions designed to deliver consistent, high-quality results.

Factors Affecting Defoamer Performance in Industrial Foam Solutions

When it comes to successful foam control additives, defoamer performance depends on several crucial factors. Understanding these helps ensure you get the most out of your foam suppression chemicals, whether in coatings, wastewater treatment, or printing inks.

Compatibility with the System

One of the most important aspects is compatibility. Your defoamer must work well with other ingredients in the formulation, such as solvents, pigments, or emulsifiers. Using the wrong type, like a silicone-based defoamer in a system not designed for it, can cause poor dispersion or even create more foam.

- Match the defoamer to your formulation to avoid issues like separation or reduced effectiveness.

- Consider the pH, temperature, and chemical environment to ensure stability.

Correct Dosage and Timing

Using the right amount at the right time is key. Too little defoamer won’t suppress foam effectively, while too much can cause defects like surface irregularities or reduced product quality.

- Start with manufacturer-recommended dosages and adjust based on foam levels.

- Apply defoamers at stages where foam forms—often during mixing, agitation, or processing.

- Monitor foam levels continuously for any need to tweak dosage.

Environmental Conditions Impact

Environmental factors like temperature, pH, and agitation intensity influence the defoamer mechanism. For example, high temperatures might reduce the efficacy of some defoamers, while strong agitation can cause foam to reform if the defoamer isn’t properly formulated.

- Choose defoamers designed to withstand your operation’s temperature range and chemical conditions.

- Remember that wastewater treatment plants and industrial processes often face varying conditions, so robust defoamers are needed.

Avoiding Side Effects

Using defoamers isn’t just about knocking down foam—it’s also about avoiding unwanted results like pinhole defects in coatings or residue buildup that can affect product aesthetics and function.

- Ensure the defoamer formula doesn’t interfere with drying times or surface finish.

- Watch for foam reformation issues, which may require additional treatments or combined antifoam approaches.

- Select defoamers that align with regulatory compliance and environmental standards, especially for eco-friendly options.

By carefully considering these factors—compatibility, dosage, environment, and side effects—you can maximize the efficiency of your defoamer products and maintain consistent, high-quality results across your operations.

Choosing the Right Defoamer for Your Needs

Selecting the right defoamer is crucial for effective foam control additives tailored to your specific process. Foam problems vary widely across industries, so understanding your situation is the first step.

Assessing Foam Type

Different foams need different solutions. Identify whether you’re dealing with:

- Stable foam: Long-lasting, often found in coatings and inks.

- Unstable foam: Breaks down quickly but may reform in processes like wastewater treatment.

Choose a defoamer with the right mechanism—some work by spreading to disrupt foam bubbles, while others absorb or collapse them. Matching the defoamer action to your foam type ensures better control.

Industry Specific Needs

Each industry has unique foam control challenges:

- Defoamers for coatings and inks require pinhole prevention and excellent compatibility with solvents.

- Wastewater treatment defoamers need to work under harsh conditions without affecting water quality.

- Industrial foam solutions in food or chemical manufacturing must meet safety and regulatory standards.

Understand your industry’s requirements, including whether you need silicone-based defoamers for strong coverage or polymer-based options for gentler foam suppression chemicals.

Eco-Friendly Options

Sustainability is a growing concern in the US market. Many customers seek eco-friendly defoamers that minimize environmental impact without compromising performance. Look for:

- Biodegradable formulas

- Low VOC content

- Compliance with EPA and local regulations

Offering these options gives you a competitive edge while supporting your company’s green initiatives.

Testing and Customization

No one-size-fits-all exists in foam control. Testing defoamers in your actual process is essential:

- Trial different dosages to find the optimal balance

- Monitor foam reduction and any side effects like surface defects

- Work with suppliers who offer customization to fine-tune formulas based on your feedback

At Blissam, we understand how important tailored solutions are. We help you evaluate defoamer performance for your specific use, ensuring reliable, efficient foam elimination that matches your production goals.

In :

- Identify your foam type

- Match defoamer technology to your industry

- Consider eco-friendly, compliant options

- Test and customize to fit your process

This approach guarantees you get the best foam control solution for your needs, boosting product quality and operational efficiency.

Common Challenges with Defoamers and How to Solve Them

Using defoamers effectively isn’t always straightforward. Some common issues can pop up during foam control in coatings, inks, and other processes. Here’s how to handle the main challenges:

Pinholes in Coatings and Inks

Pinholes occur when tiny air bubbles get trapped in paints or ink layers, ruining the smooth finish. This often happens if the defoamer doesn’t disperse well or reacts poorly with the formulation.

How to prevent pinholes:

- Choose the right defoamer type: Silicone-based defoamers work great for most coatings, but sometimes non-silicone options are better for sensitive inks.

- Adjust dosage carefully: Too little defoamer won’t control foam; too much can cause defects like pinholes.

- Proper mixing: Ensure the defoamer is evenly dispersed to break foam early before bubbles get trapped.

Foam Reformation

Sometimes foam comes back after appearing to disappear. Foam reformation wastes materials and time, especially in wastewater treatment and industrial processes.

Solutions:

- Use long-lasting defoamers with good spreading properties.

- Combine mechanical foam control (like agitation) with chemical defoamers.

- Monitor process conditions such as temperature and pH, as they can affect defoamer efficiency.

Regulatory Compliance

Many industries, especially in the U.S., face strict rules on chemical additives regarding safety and environmental impact. Using defoamers that don’t meet regulations can cause costly recalls and fines.

Stay compliant by:

- Selecting eco-friendly defoamers certified to meet EPA and FDA standards.

- Avoiding harmful solvents and toxic ingredients.

- Keeping clear documentation for all chemical agents used.

Blissam’s Expertise in Foam Control Solutions

As a leading U.S. manufacturer and supplier of chemical agents and defoamers, Blissam understands these challenges well. We offer:

- Tailored defoamer formulations for specific industries like coatings, inks, and wastewater.

- Products tested for optimal performance and minimal side effects.

- Support on regulatory compliance and product selection.

- Access to eco-friendly, silicone-based, and non-silicone defoamers to match your process needs.

When foam control is critical to your operation, partnering with Blissam ensures you’re equipped with reliable, efficient defoamers designed for the American market and regulatory landscape.